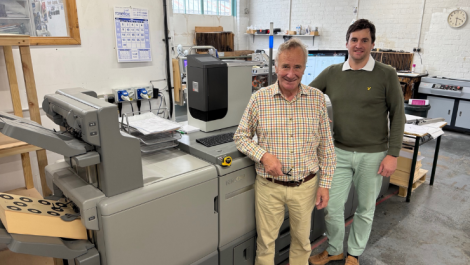

David Woodcock, operations director, with the KAS Mailwrap

Leeds-based Resource Print Solutions is now able to bring wrapping in-house with the addition of a KAS Mailwrap polywrapper complete with exit camera reading.

The company, which offers a full campaign management service and support from concept to print and fulfilment, was spending up to £70,000 a year on outsourcing its polywrapping.

David Woodcock, operations director, said, ‘The cost of outsourcing led us to consider purchasing our own polywrapper. In addition, the need for tight control of sensitive, personalised data had become an even more important issue after we were awarded ISO 2701 accreditation for information security management.’

The company specified the Mailwrap with four insert stations and a hand feed option to meet all their demands. ‘Our longest run length is about 35,000 packs but typically it is between 5-12,000 packs, each containing between two to five inserts, which the Mailwrap handles well.’ commented Mr Woodcock.

Its capabilities extend to wrapping up to 22 mm thickness. ‘We have an Oce 4120 black and white printer, an HP Indigo 5000 digital press and a Mitsubishi litho press and we are shortly to add a Ryobi SRA1 5 colour press when we relocate to larger premises. We print newsletters from 16-36 pages but we also send out reply envelopes, rent statements, letters and even raffle tickets.’

As the inserts are sequentially numbered with a 2D bar code, the company required an exit reading camera to check that the correct documents are inserted into each pack. If there are any mismatches then the machine stops automatically. ‘It did require some initial modifications to meet all our requirements but this was expected as we were the first customer with datalog installed on a Mailwrap. It is now running very well,’ Mr Woodcock concluded.