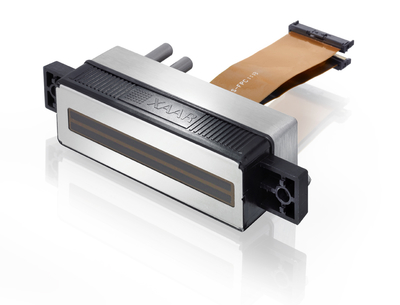

Xaar has launched the Xaar 1002 AMp printhead, the first in a new range of piezoelectric drop-on-demand printheads designed specifically for advanced manufacturing applications.

The printhead is suitable for very small drop fluid deposition on an industrial scale and is capable of consistently jetting droplets as small as 1 pL for the production of fine features, patterns and coatings. The combination of highly accurate, very small drops and reliability enables the industrialisation of advanced manufacturing processes in sectors such as display, PCB, semiconductors and photovoltaics.

Many applications require tight regulation of coating thicknesses, precise patterns and management of substrate surface characteristics. This printhead is built to combine highly accurate drop placement, consistent drop volume and high frequency jetting with variable drop size capability to deliver the precise fluid control essential for these processes.

‘Developing inkjet as an advanced manufacturing process is hugely challenging,’ said David Chapman, who is responsible for developing Xaar’s Advanced Manufacturing business. ‘Every application is unique with its own functional fluids and exacting print demands. What you can achieve in a lab is often almost impossible to replicate in a high efficiency manufacturing environment. The new Xaar 1002 AMp printhead is built on a proven high performance industrial inkjet platform and is supported by Xaar’s unique experience in fluid handling and equipment integration to help our partners develop bespoke manufacturing solutions.’

The 1000 Optimised Geometry nozzles gives accurate jetting and consistent drop volume across the printhead, even with fluids that have a high solid content, including metallic particulates. The TF Technology ensures a uniform temperature across the whole printhead for consistent drop formation and repeatable fluid deposition. In addition XaarDOT optimises drop size, drop formation and fluid performance to achieve the combination of quality and speed. It also enables variable drop volumes within a single pattern to control coating thickness and avoid potential optical effects such as banding and Mura.

The 1002 AMp is supported by the modular and slim line HPC3 and XUSB drive electronics, plus the Hydra ink delivery system, so it is easy to integrate and, if required, multiple printheads can be configured into large jetting arrays.