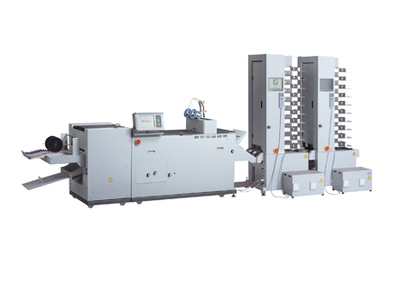

A Horizon SPF/FC-200A

Robson Print has expanded its production capacity following investment in a Horizon SPF/FC-200A stitch, fold and trim line supplied by Intelligent Finishing Systems Ltd.

Return on investment is expected in fewer than 18 months according to Neil McKie, director. He stated, ‘We don’t pigeonhole any of our operators on particular pieces of equipment. We like them to be able to operate lots of different systems and the Horizon fits in well with that. It was a lot easier to set up than the older machine and our apprentices were up and running on it very quickly.

‘The programmability is very useful. We recently had a 3000 run that we interrupted for a small 500 book job for Waitrose. It also offers extremely smooth operation, which gives us more confidence to take on the bigger jobs. We can just set it up and let it run.’

The company’s system features a 200 programme job memory storage for instant recall, an icon-based touchscreen for job set-up and two 10 station VAC-Turbo 100 PowerCollators.

The suction rotor drum feeding system operates effectively on a wide variety of paper stocks at high speeds. Accuracy and reliability are assured by mis-feed, double feed and jamming sensors on each bin and the feed error history can be monitored via the touchscreen.

‘Collating used to be a big bottleneck and the Horizon has made a massive impact,’ said Mr McKie. ‘Going from 10 stations to 20 is saving us days at a time. There is no need to pre-collate now. We have also significantly increased capacity and we are getting through the work much quicker. We are getting a good throughput and work keeps coming in.’

A punch unit has also been added to the unit. ‘We have a regular 3000 book run but it can be as much as 12,000 books, so we took a considered gamble and added the punch to the system to handle this one job much more cost effectively. But we also hope it will help us win similar work,’ concluded Mr McKie.