Canon Europe has installed its first liquid-toner based InfiniStream technology at packaging printer Joh. Leupold GmbH, based in Schwabach, Germany.

Complementing Leupold’s existing fleet of high end offset printing presses, the InfiniStream will provide digital short to medium length production runs for Leupold’s customers, who consist of global brand owners and local German brands.

Leupold offers a complete range of services for folding cartons, point of sale displays and presentation boxes. With innovation a key principle of the business, it is the first customer in the world to install this digital technology as part of Canon’s ‘Proof-of-concept’ commercial printing customer programme.

The Océ InfiniStream Technology offers productivity at offset level coupled with minimum set up times and a capability to individually modify contents and artwork, thus paving the way for real mass packaging customisation with the shortest possible time to market.

It combines the advantages of offset printing with the many benefits of digital printing, delivering time, cost and value improvements in folding carton production. The InfiniStream is the ideal solution to the increasing demands in the packaging value chain for shorter run lengths, waste and cost reduction and reduced turnaround times for faster campaign execution.

Bernd Assmann, managing director, stated, ‘During discussions with brand owners, it became evident that trends such as declining run lengths and increasing use of versioned products will become major challenges in the packaging value chain. Brand owners are requesting shorter turn-around times and faster campaign execution, as well as waste and cost reduction.’

‘We have carefully analysed the market so that we can ideally address these requirements. It was clear that the InfiniStream technology is the way forward as the answer to major trends in the packaging market. That is why we are taking advantage of a completely new press category, the fastest in the industry, in digital folding carton production.’

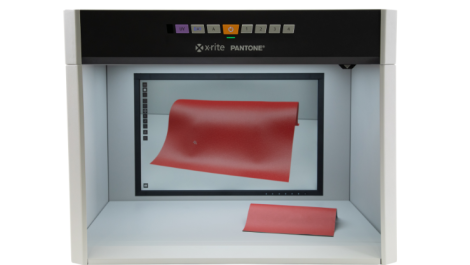

The machine is based on an electro-photographic liquid toner technology that matches offset in relation to productivity, print quality and substrate versatility. With its roll-fed, modular print tower architecture, customers can select from four to seven colours, depending on requirements. Running at up to 120 m/min it can produce output of up to 14,400 B2 sized or 7,200 B1 sheets per hour on a 28 inch wide web.

Compared with offset and depending on the specific job parameters, the machine will deliver a cost advantage for run lengths up to 3000 to 4000 B1 sheets. Through an offset like image transfer with a rubber coated transfer cylinder, it can also handle standard offset cardboard substrates up to a thickness of 600 microns.