Esko is set to launch a new Kongsberg digital finishing platform during the 2013 SGIA Expo, to be held 23-25 October in Orlando Florida.

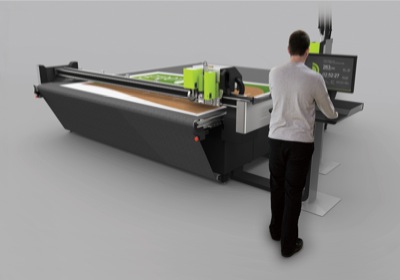

The company describes the Kongsberg C64 as an extremely fast and accurate 3.2-meter wide cutting table.

Steve Bennett, vice president, said, ‘This is not just a new Kongsberg table, it’s a completely re-engineered and redesigned platform for Kongsberg finishing systems. We call this the C-series after a decade of the highly successful and well known Kongsberg X-series.

‘Among the many great new features, one of the eye catchers will be the innovative composite traverse technology that provides the fastest throughput along with the highest quality and precision in cutting and routing compared to all other systems of the same size. Just as impressive, the Kongsberg C provides the highest versatility for all sign, display and packaging applications. It does all this while making it easy to use the machine – from the new, simple interface to the ease of replacing tools on the table.’

At SGIA, the company will demonstrate the Kongsberg C64 model: it works with 3210 mm x 3200 mm materials to accommodate today’s large format printing sizes. Also available is the Kongsberg C60 model to accommodate 3210 mm x 1600 mm sizes.

The i-cut Production Console is the front end to operate and manage the Kongsberg digital finishing systems. The i-cut Production Console is designed for all applications on all Kongsberg tables.

The company features a wide range of integrated solutions for the sign and display industry, spanning from design to print to cut, withi-cut SuiteThe suite is an InterTech Technology Award recipient and lets companies that drive narrow or large format digital printers and/or digital finishing systems streamline their workflows.

It preflights and edits incoming PDF files, ensuring that jobs will RIP and print correctly. It also helps build and edit sheet layouts, ensuring that jobs make the optimum use of substrates through intelligent true shape nesting and tiling. Kongsberg table technology ensures that die-less cutting contours match printed images perfectly, registering the actual dimensions and positioning cuts on the printed result. With i-cut Automate, all of these functions are automated in a single workflow, with less operator intervention