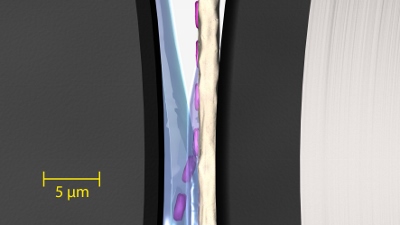

The transfer of the liquid toner from intermediate roller to paper – the micro-gapping of 5 microns is clear.

Xeikon has revealed further details and an update on progress with its new liquid toner technology, named Trillium, which was first shown as a demonstration at drupa running at a metre a second.

Its intention is to deliver high speeds and low cost of output comparable to offset and inkjet technologies, while producing electro-photographic quality print.

Xeikon’s Danny Mertens explained: ‘Traditional print houses that are looking to invest in new digital equipment would be looking for 100% dynamic print, with every print different; they would be looking for low cost, high speed, no drying time or set up time, and maybe even an easier way to operate. If you’re a digital printing house already, you would be looking for higher quality, on a wider range of media, with higher coverage, and preferably the print should be recyclable. With Trillium we can tick all these boxes at the same time.’

The first product to use the Trillium technology will be a roll-fed press, aimed at high quality direct mail and publishing applications such as magazines and books, where versioning has yet to take off because the market lacks a suitable digital printing technology. Coated papers are the focus for these markets, and Xeikon claims ‘excellent results’. The company is currently selecting a first beta test customer, which will be in Europe and will start in Q1 2014. The product itself will be launched worldwide in the spring of 2014.

The four rollers of the Trillium print station.

The key to the performance of the technology lies in the ‘micro-gapping’ between the rollers in Xeikon’s print towers. Very fine toner particles of two to three microns are mixed with a carrier oil. The liquid toner is transported between an anilox roller, via a doctor roller, to a photo conductor roller, and then again onto an intermediate roller, which transfers the image to the sheet. Most importantly, the gap between each of these cylinders – the micro-gapping – is just five microns. In comparison, said Xeikon, dry toner and LVT liquid toner systems in general have a gap of 200 microns, while inkjet technologies typically have a 1500 micron jump. Any excess carrier oil is recycled.

Micro-gapping again in evidence. Excess toner and carrier oil is recycled.

Some numbers: print quality is stated as 1200 dpi but the small particle size and micro-gapping gives a very smooth additional look and feel to the sheet; the first production press will be running at 60 metres per minute (800 A4 images per minute); monthly duty cycle is stated as a minimum of five million A3 prints per month; imaging width is about 500 mm; substrate options currently range from 60 to 250 gsm, coated and uncoated.