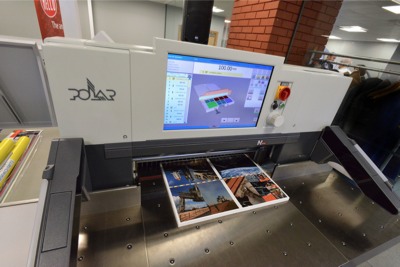

4edge has improved efficiency and is now able to speedily call up cutting programmes with the addition of a barcode reader on the Polar 78 Pro guillotine.

The investment was a necessary step due to the limited supply of papers from mills and a need for a higher level of output. With a strong line in books and journals, grain direction is extremely important to the Southend printer and finding less choice of long and short grain B2 options available, the company has decided to buy B1 sheets to cut down.

‘There are many guillotines out there and we reviewed carefully before deciding on the Polar. It ticked all the boxes and it is future-proof. We went for the top of the range Pro version because we liked the larger 23 inch screen, the operator assists and the fact its operating system and JDF compatibility means it can work with a range of MIS systems.’ said managing director David Button.

This was important to the company as it looks to replace its bespoke MIS system but only when it can find a solution that can allow it to create jobs as fast as its own, which uses ISBN unique book codes to set up a job. The company prints with the latest generation Océ printing presses and state of the art binding and finishing equipment

The guillotine installation is almost concurrent with the company’s tenth anniversary. It is a digital plant that set up with colour and black and white digital printing equipment then supplied by Heidelberg. ‘Heidelberg is a trusted partner. We know they always resolve issues,’ said Mr Button.