Under the skin of a Landa press.

Six months after it appeared for the first time at the drupa show, Landa has released a downloadable White Paper that explains in layman’s terms how its new Nanography process works.

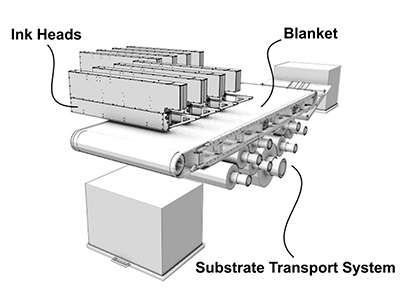

The white paper highlights how Nanography differs from other printing technologies. It employs Landa NanoInk colorants, proprietary water-based inks with ‘nanopigment’ particles that are merely tens of nanometers in size. These are sprayed by inkjet heads (Landa calls these ejectors) onto a moving, heated blanket. The heat drives off the water leaving adhesive ink particles that are then brought into contact with the substrate. The ink s effectively dry as soon as it is applied. This means that normal offset papers can be used, as well as plastics and packaging materials.

Actually the white paper is as much a marketing proposition as a technical publication and at first sight there’s nothing in there that wasn’t mentioned in the hugely popular Landa Theatre presentations at drupa and expanded on somewhat during founder Benny Landa’s subsequent talks with technical journalists. Digital Printer published its technical take on Nanography and the Landa presses in July, here.

Cutaway view of a Landa S7 sheet fed press.

However, the white paper includes more diagrams and microscopic photographs (almost all were first shown in the presentation) and puts things into the company’s own words. If you missed the drupa presentations or want a reference to what was said, it’s worth reading the White Paper (though you’ll get more detail on the presses and markets in the Digital Printer story).

A sample Nanography print from a Landa prototype press, displayed at drupa in May.

The White Paper covers:

* The characteristics and limitations of current digital printing technologies.

* The unique properties acquired by materials when reduced to the size of nanoparticles.

* A description of Landa NanoInk and the Nanographic Printing process.

* The special characteristics of dots printed with Landa NanoInk.

* The transfer of the printed image to any substrate.

* It also claims that the Nanographic process can yield the lowest cost per page of all digital printing technologies.

Gilad Tzori, Landa’s vice president of product strategy said: ‘The white paper is designed to both educate the market on the Nanographic Printing process and highlight the economic advantages and eco-friendliness of the technology. It also demonstrates our commitment to provide our customers with information on an ongoing basis as we continue the work on product development and bring the presses to full commercial availability.’

Contact: www.landanano.com/white-paper