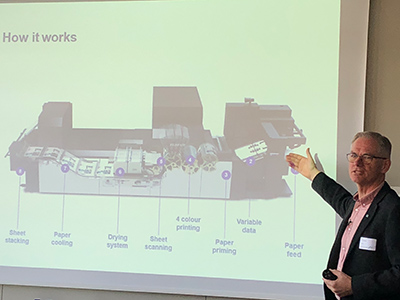

Fujifilm’s Mark Stephenson explaining the enhancements in the new inkjet press

Fujifilm has launched the Jet Press 750S, its third-generation B2 inkjet, in Europe, offering increased productivity from a smaller footprint and features aimed at the folding cartons sector.

Featured earlier this year in Digital Printer, the Jet Press 750S has a slightly larger format, printing on 750 x 585mm sheets, and comes with the option to print on substrates of up 600 microns thick, presenting a new opportunity for digital folding carton production.

Building on the Jet Press 720S, the press come with a new hot air drying system and heated transport belt, along with optional 100% inspection, which can also be focused to check specific areas. A new printhead retraction system with a sensor will detect any faulty sheets and lift the printheads out of harm’s way while they pass through. This avoids stopping the press completely and is one of several improvements that enables higher productivity. Print speed is 3600 (single sided) sheets per hour, a 33% increase on the 720S, and the resolution of 1200 x 1200dpi comes from next-generation Fujifilm Samba printheads, which now also feature an overflow cleaning systems that reduces head cleaning frequency and automatic nozzle control to correct deviations and deposition inconsistencies on the fly.

The water-based Vividia inks (CMYK) have been tested to meet food safety regulations and are approved for non-food contact primary packaging. Sheets still need pre-coating to optimise and control dot formation. This also prevents the ink from sinking into the substrate which means waste can be recycled using normal deinking processes.

Tilia Labs’ Phoenix impositioning will link with Fujifilm’s XMF workflow for carton production, while Fujifilm’s XMF workflow software will provide the usual functionality for commercial applications. XMF has been further developed to offer the ColorPath Brand Color Optimizer, which will predict the accuracy of brand colours before commencing production. This is said to match 90% of Pantone colours with CMYK to within a Delta E of 3, which meets the ISO 12647-2 offset specification for accuracy.

The target market for the packaging version is food, pharmaceuticals, household and cosmetics/personal care, while the increased productivity and wide colour gamut should also appeal to high quality commercial printers.

Fujifilm also announced the first two customers for the Jet Press 750S: commercial printer Floricolor in Portugal and Mediadruckwerk in Germany. The latter is a major full service print business employing 60 people and producing a wide range of products, from postcards and greetings cards, to brochures, calendars, posters and short run books.

‘Like print businesses everywhere, we’re seeing a continual trend towards demand for shorter runs and faster turnarounds,’ said Mediadruckwerk CEO Sven Kohlmeier. ‘This has been ongoing for some time and as a result we began investing in digital print technology around 20 years ago. Since then, digital print has come a long way both in terms of quality and reliability, and we feel that the Jet Press 750S sets a new high standard for both in the digital print market. […] the increased speed opens up the real possibility for us to move a significant amount of short to mid-run work from our offset presses.’