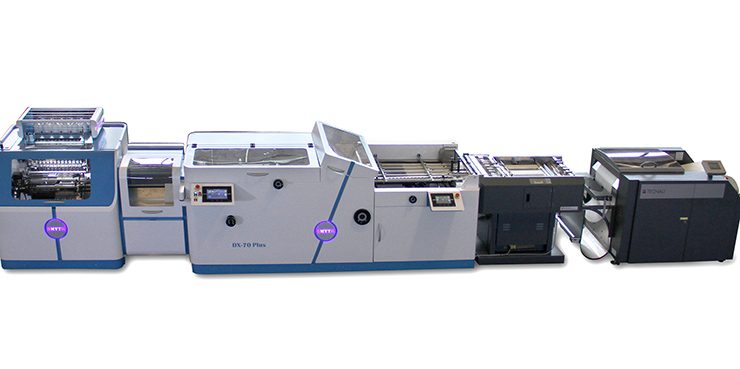

Roll-fed finishing manufacturer Tecnau and book-binding specialist Smyth have together developed a folding and sewing system for continuous-feed production of digitally printed books and catalogues.

The solution unwinds, cuts and stacks 4- and 8-page printed signatures which are folded and collated to form larger signatures that are then sewn. The Tecnau input feeder, comprising an Unwinder u10 and Cutter TC7000HS, makes it possible to process variable page lengths completely automatically. This can be done without any operator intervention and at up to 600 signatures per minute.

The cutter allows for effectively instant speed changes and stoppages, which simplifies the book-block separation process during sewing. Smyth’s DX-70 Plus features two parallel pockets followed by the collating station, allowing the production of multiple 16-page signatures printed on a single sheet, also reducing costs and production time.

The system is said to guarantee ‘dramatic’ cost and time savings, while being simple enough to use that the entire process can be managed by a single operator.

‘Together we’ve created a fully integrated system for sewn book-block production from a continuous feed at high speeds,’ commented Stefano De Marco, sales manager at Tecnau. ‘Roll input maximises digital print production, guaranteeing high volumes, reduced costs and an always-increasing print quality that well matches the finishing quality of the sewn books.’

Sabrina Pronotto, CEO at Smyth, added, ‘This thoughtfully engineered solution can easily manage a wide array of applications from short to medium runs for book-on-demand production.’