Fujifilm has announced that its well-established XMF workflow suite has been ‘fully’ integrated with Tharstern MIS and EFI’s Pace. These integrations streamline print production and should bring increased productivity, improved client communications and lower costs.

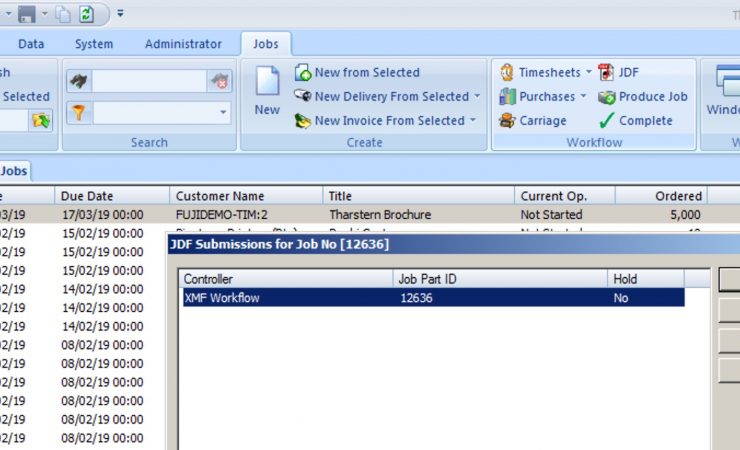

The integration with Tharstern allows advanced automated production direct from the MIS into the XMF workflow. A key benefit is the ability to deliver additional PDF content attached to an MIS job, with the help of automatic page assignment for future reference. This enables print providers to streamline the delivery of artwork throughout the organisation, and allows old jobs to be visible after they have been archived and deleted from XMF. Fujifilm says this is especially beneficial for web-to-print workflows.

A further advantage is that print jobs can be created automatically. Jobs created in the MIS are pushed directly into XMF, including the full job description, customer details, product details and imposition requirements. This saves time and ensures that jobs are created consistently.

The integration with EFI Pace brings complete two-way end-to-end workflow integration. XMF’s messaging to Pace automatically completes all prepress job plan activities in Pace Scheduling. A job can be submitted to XMF directly by Pace and automatically processed in XMF. Once done, XMF sends information about the production timings and the number of plates in litho jobs used back to the MIS and the data is stored.

John Davies, Workflow Product Group manager at Fujifilm Graphic Systems Europe, says, ‘Fujifilm prides itself on partnering with the very best technology providers and developers available, and these new integrations are the latest example of that. We have had the ability to take in print jobs from MIS systems since XMF was first introduced in 2007, but integrating with the Tharstern and EFI Pace MIS systems marks a significant step forward.’