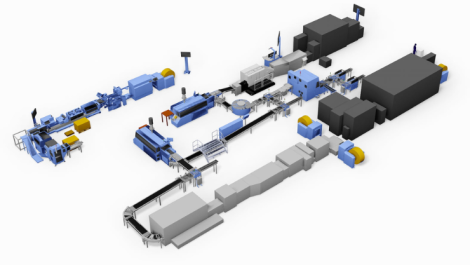

Integrity Print has installed a fully integrated finishing line to complement its high speed web-based digital and analogue printing operations at its site near Bath.

Supplied by Friedheim International, the line incorporates a sheeter, folder and stacker, with Hunkeler off-line roll-to-cut and stack sheet lines running at approximately 150m/min, an MBO T535 buckle folder with A500 stacking delivery and Herzog Heymann transfer stations bringing the potential speed up to 205m/min.

In addition to litho and flexo the line will finish work printed by Integrity Print’s mail division, which operates Xerox Versant (colour) and Nuvera (mono) ranges, as well as digital presses from Canon Océ and Riso.

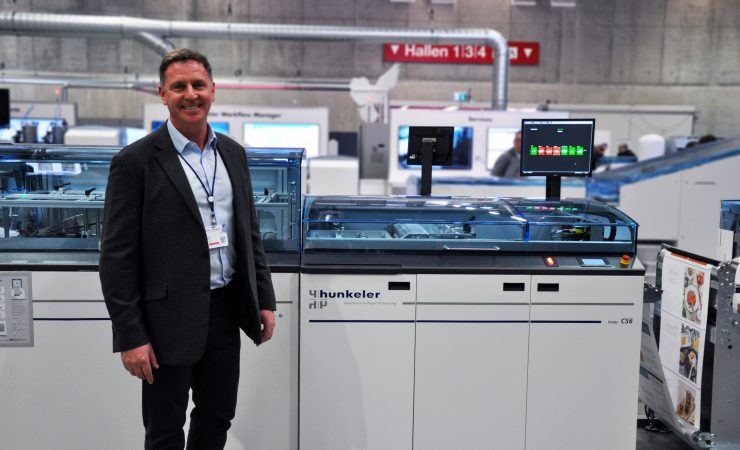

‘We initially started looking purely for a deep pile sheeter,’ explained managing director Mark Cornford, ‘but Friedheim, after reviewing our requirements, came up with a proposal to build a fully integrated sheeter, folder, stacker line.

‘This allowed us to improve process flow and massively increase capacity, in fact we’ve almost tripled our capacity with the new line.’

On Integrity’s current and future plans Chris Walton, head of Transaction, said, ‘Installation went very well and met all the planned schedules, and the two Friedheim engineers delivered a comprehensive training programme to our staff with a follow up session being planned later in the year. Our customers are extremely supportive and excited with the obvious opportunities and flexibility that a ‘white paper solution’ will bring. We hope to be in a position to make a positive announcement during Q2.’