Bishops Printers, a commercial print and direct mail business, has installed two new Muller Martini saddle stitchers, meaning it has now invested over £5million in new equipment since the beginning of 2019.

The Portsmouth-based company began its spending spree with the purchase of two Heidelberg offset presses, before bringing in a seven-colour HP Indigo 12000 to enhance its growing digital print division.

Commenting on the unusually high level of investment, managing director Gareth Roberts reflected: ‘When you’re directly responsible for the livelihoods of 270 people and your decisions impact on a much wider network of valued suppliers and loyal customers, decisions like these do weigh heavily. Committing to an annual investment programme has never been easy for us to do, but I believe strongly in keeping the business relevant and responsive to market changes, and we can’t do that by standing still.’

With all the new machinery up and running the £26 million turnover business, which is still family owned, 35 years after its founding, expects 2020 to be a record breaking year.

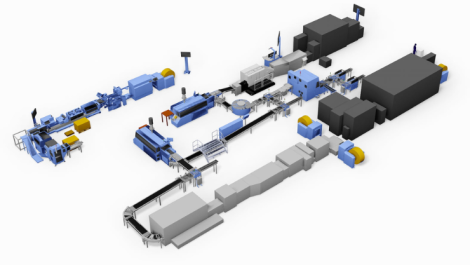

‘Müller Martini is very pleased to be part of Bishops Printers’ on-going success,’ said the company’s UK sales manager David McGinlay. ‘The new lines are amongst the most advanced saddle stitchers in the world and will prove to be game changers, when in full swing. Net output was one of the key factors in Bishops’ decision along with short make ready times. Two-up production will double the improved output even further and with the addition of loop stitiching they now have the power, agility and extra flexibility to further strengthen Bishops Printers’ position in these ever changing markets.’

HP Indigo country manager Peter Jolly added, ‘With run lengths reducing, but volume increasing, the installation of the HP Indigo 12000 B2 Digital press has enabled Bishops to become even more responsive, no matter what the size of order. In addition to satisfying shorter print runs, with offset quality, the HP Indigo 12000 also enables Bishops to offer greater variable data printing for personalised print products.’