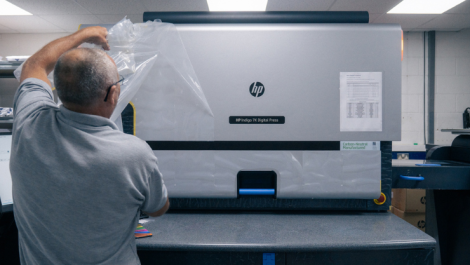

Signarama Birmingham South, based in Solihull, has installed an HP Latex 365 to accelerate production of vehicle wraps. The machine was installed in September of last year, replacing a solvent printer.

Unlike solvent, printing with latex ink requires no lengthy outgassing times – allowing graphics to be printed, laminated and applied much faster – while producing high-quality, durable output.

‘In the sign trade, customers are becoming more demanding and placing more last-minute orders. With HP Latex, we can be more reactive,’ said Jeremy Andrews, who founded the Signarama franchise eleven years ago. ‘The process is so fast – from printing to laminating then applying – that we can now eliminate potentially costly errors by waiting until a vehicle is delivered, and checking its dimensions, prior to printing and applying the graphics.

‘Previously, our solvent printer would have needed gassing off time if there was an error, meaning not only would we lose the cost of the vinyl, but also production hours. But, with the new HP Latex machine, we wait until the vehicle is delivered, alter the graphics dimensions if required – and print and apply them within a day. Overall the print and install process is just great.’

The franchise specialises in a range of wide-format printing applications including advertising banners, exterior business signage and bespoke projects such as wall art, as well as vehicle graphics. It serves a number of businesses in the local community, counting Birmingham Airport, Jaguar Land Rover, Travis Perkins and the National Motorcycle Museum among its customers.

Mr Andrews has hinted that Signarama Birmingham South may expand into bigger premises in 2020, with the benefits offered by HP Latex potentially helping to grow its service offering too.