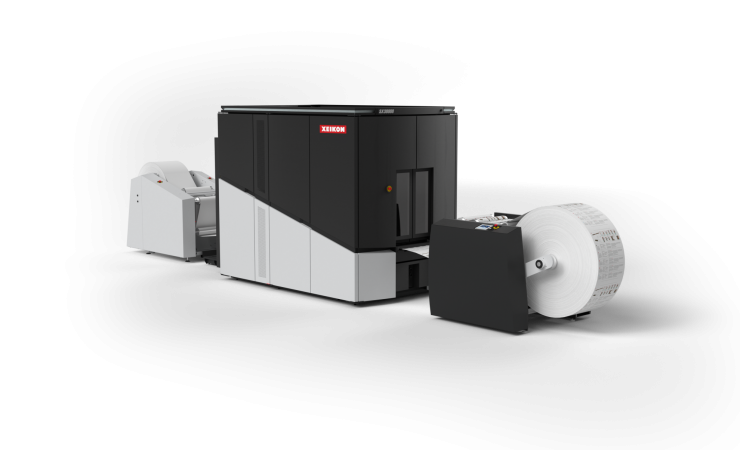

A new web-fed toner press from Xeikon offers the equivalent of over 400 A4ppm, setting it squarely against cut-sheet SRA3 and low-end web inkjet presses as well as B2 toner and inkjet models from other vendors, but with the substrate flexibility and high coverage image quality associated with toner print.

The SX30000 is the first implementation of a new technology platform that Xeikon calls Sirius. The 520mm (printable width 508mm) single-pass duplexing web press runs at up to 30m/min, equivalent to 404ppm or 2500 B2 sph, which it can maintain on stocks up to around 200–250gsm; it is almost three times as fast as previous Xeikon presses on 300gsm, according to Xeikon’s Dmitri Van Gaever. To achieve these speeds, Xeikon has worked on media conditioning, imaging, fusing and the toner. LED-based imaging operates at 1200 x 3600dpi, and is said to yield ‘offset-like’ quality, via eight imaging stations (CMYK both sides, upgradeable to 10 to allow one additional colour). The new toner generates fully recyclable print and the process requires no water or fuser oil.

Fusing to keep up with the speed of print is achieved via a new design called EcoFuse, which uses foil heating elements to provide rapid heating and even temperature distribution; a water cooled cylinder is used to remove excess heat after the fusing process and this allows printing on cheaper stocks. Both of these elements are expected to last the life of the press and are not classed as consumables. Image quality is maintained via a built-in spectrophotometer for colour accuracy and a registration camera for dimensional stability. Adjustments are performed automatically on-the-fly, making the SX30000 a ‘cruise control’ press, according to Mr Van Gaever.

Connectivity is catered for with an improved machine interface designed to give easy visibility of press status, and machine-machine connectivity for pre- and post-press paper handling and finishing. Machine data is also sent to the Cloud for MIS purposes and analysis for ‘business decision making’ or business intelligence uses.

Mr van Gaever outlined three markets where the Sirius-based Xeikon presses might sell: as complements to high-speed inkjet installations, where greater media versatility and flexibility are required; to consolidate production in dry toner print sites where more throughput is needed; and in companies limited on capital expenditure and/or floorspace. The new technology is claimed to bring a lower total cost of ownership.

A new label press, the CX300, was also announced; you can read about it here. The SX30000 will be available from the end of June, with first installations expected later in 2020.

Commenting on the Coronavirus situation, Xeikon CEO Benoit Chatelard said that Xeikon was focusing on business continuity, particularly for customers in label applications and that its toner factory is working at full capacity, supporting Xeikon’s recurring revenue business model. Work is underway to develop a ‘remote showroom’ to demonstrate products such as the new presses during the lockdown period and Mr Chatelard speculated that a consequence of the pandemic might be a move towards a distribute-then-print model, in which ‘ever growing’ digital print would be a way to ‘print as close as you can to the customer’.