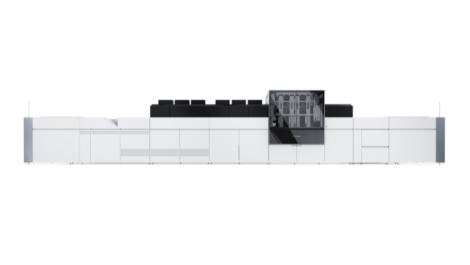

Konica Minolta has revealed the next incarnation of its B2 UV-curing inkjet press, the KM-1e. The new machine offers an increased format, reduced maintenance requirements and the ability to work with a wider range of media including transparent and coloured materials.

Launched at drupa 2016, the original KM-1 now has around 100 installations worldwide (including at Essex-based Colourfast / getitprinted.com, who printed Digital Printer’s 2020 Guide to Inkjet on it), according to Hidetoshi Omo, head of Centre of Competence for the KM-1, who added that sales had grown even in 2020, despite the Covid-19 crisis and that the aim is to double sales in the current financial year over the previous one.

Inkjet business development manager Nuno Sacadura described the new machine as ‘a bridge between offset and digital’, with features aimed at expanding its presence in the commercial print sector. Expanded paper compatibility, including embossed and textured types, support for versioning and full variable data are key to this, though not unique to the new model. Media ranging in thickness from 0.06 to 0.6mm (60 to 600 microns) is supported (though the upper limit in duplexing mode is 450micron), allowing small scale carton production as well as other applications on heavier media.

The KM-1e (the ‘e’ is for evolution) has an increased sheet size, now up to 585 x 750mm, which Mr Sacadura said is the biggest in the B2+ digital press class, comparing it to HP Indigo’s 535 x 750mm, though we note that the Fujifilm JetPress 750S also supports 585 x 750mm. As before, the press is capable of 3000 simplex impressions per hour (1500 duplex), equivalent to 200 A4 ppm, though users printing US letter size documents will benefit from the ability to fit six-up and so achieve 300 letter pages per minute.

Print is still 1200dpi CMYK only, with no current plans to add white for use on transparent or coloured media or additional primary colours to extend the colour gamut, though Mr Sacadura said that the KM-1e covers more than 80% of the Pantone range; he also stressed the image quality, front-to-back registration and colour stability, the latter governed by colour management technology similar offered with the company’s toner presses. The gloss finish of the printed area can be varied by temperature control in the UV curing stage and because of its instantly dry nature, work can be sent immediately for finishing. The cured UV ink is also said to provide a degree of durability without lamination, which supports a new application in short run sheet-fed label production, in addition to cartons or any other item for which durability would be an advantage.

A tape inserter has been added to allow different jobs to be clearly marked in the output stacker, which can accommodate 600mm depth. Paper input may be stacked to 900mm and various changes to paper setup and extended maintenance intervals should result in more overall productive time. Mr Sacadura also said that a new interface to third-party finishing equipment had been added and that Konica Minolta was in discussion with suppliers for inline coating options. Output from the KM-1e is also compatible with the company’s MGI line of digital embellishment machines.

The KM-1e replaces the KM-1 and a first installation has been made in Germany, during the Coronavirus lockdown period. Pricing was not revealed.