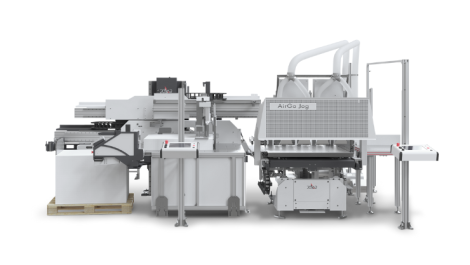

Morgana has introduced a new flat sheet UV coater, to support UV coating for protection and added visual appeal of products that are frequently handled or which have to pass through multiple finishing or mailing systems prior to receipt by the end-user. It’s also being promoted as a cheaper and more environmentally friendly alternative to lamination.

Called the DigitCoater Pro 400, the SRA3 unit is available in two configurations, using different UV curing technologies. There is a cold lamp UV version able to produce up to 45m/min and an LED one capable of 60m/min. Both variants are suitable for inline or offline operation and consume 2 – 4g/sqm of coating. Various coatings are available, including gloss, matt and antibacterial finishes.

The cool curing technologies avoid the high temperatures associated with conventional mercury lamp coaters, so avoiding potential scorching of the stock and fire hazard, and deliver finished sheets at room temperature, which Morgana says should limit distortion or shrinkage of the sheets.

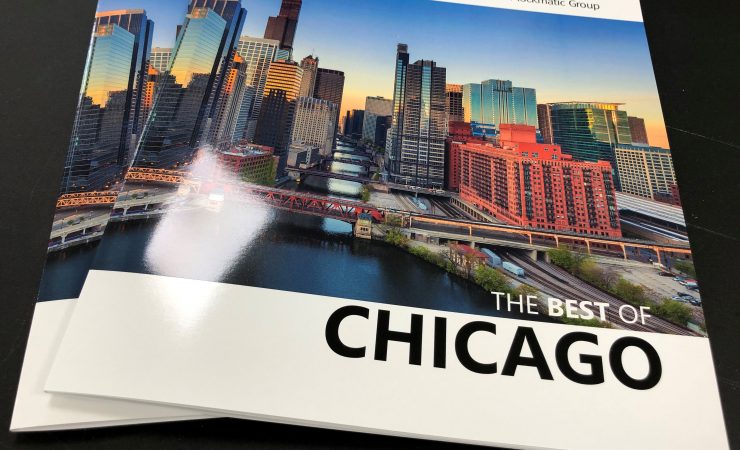

Ray Hillhouse, VP Sales & Marketing for the Plockmatic Group Offline Business Unit, said, ‘With coated sheets already a fraction of the cost of lamination, we are now delighted to introduce a product that we believe can provide the lowest cost per sheet achievable on any UV coating machine in its class. Additionally, the unique curing system on the cold lamp UV unit uses significantly less power to cure when compared to other open lamp systems on the market.’

Mr Hillhouse also noted that the coaters would typically be sold with feeders, the 2000-sheet capacity VFL vacuum feeder being the most likely, as it supports long sheets up to 1300 x 285mm and up to 600gsm, compared to the 660 x 356mm of the VFX feeder, though the latter offers higher capacity at up to 5400 sheets. The VFX model can be used with all Morgana booklet-makers.

The DigiCoater Pro 400 is available from February 2021, with remote live demonstrations available from Morgana’s Milton Keynes showroom.