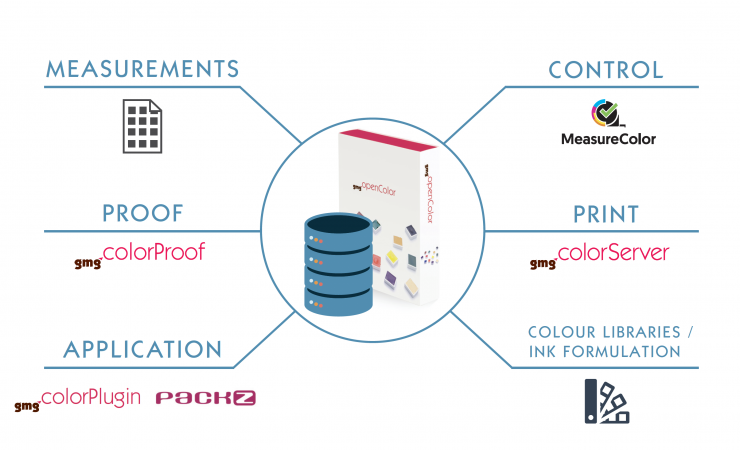

GMG has added connectivity to Colorware’s MeasureColour software for its OpenColor centralised colour management system, enabling more automation of colour matching and process control across a variety of press and proofer types.

Under the new agreement with Colorware, the GMG OpenColor libraries are now available to MeasureColor users, allowing for more extensive process optimisation. MeasureColor supports offset and digital presses, and measures attributes such as spectral curves, CieLab colour values, dot gain-like behaviour (sometimes referred to as tonal value adjustment in non-conventionally screened print), solid colour densities and spectral grey balance.

Two modes of data presentation from measured samples are offered within MeasureColor. The first is a simple traffic light system for digital press operators who are not skilled in colour management terminology and techniques, where green means ‘all is within tolerance’, yellow indicates that press calibration is required and red essentially means ‘call for expert help’. The second is the full spectral data, dot gain and trends analysis for specialist interrogation, interpretation and adjustment.

The integration between GMG OpenColor and MeasureColour means that the same spectral colours can be printed and measured via the latter as are used in the former, making matching between proof and press closer and simpler to achieve. In the digital print environment, where a proof might only be a one-off print of a job from the same machine that is going to do the entire production run, the focus is more on maintaining consistency within that machine over time, or across a fleet of digital presses, not necessarily from the same manufacturer.

GMG marketing manager Amy Young told Digital Printer, ‘The GMG OpenColor/MeasureColor connector works the same way for digital print as other print processes. It closes the gap between prepress and the shop floor as you can measure on press what is on the proof. Using a single set of references means one source of truth, enabling you to control the press consistently. It’s a case of measure once, use in many applications.’