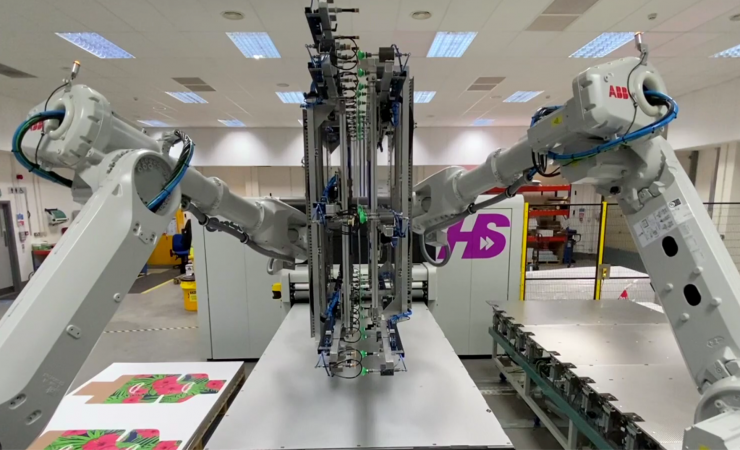

A range of robotic automation options for the Inca OnsetX HS range of flatbed printers has been introduced by Inca and Fujifilm, allowing overall throughput to be increased.

The Onset X HS (high speed) range was introduced in June 2019, and offered the highest production speeds then available in flatbed printing. Inca has been working on automation options since then and those announced today are said to ‘slash job changeover times and reduce the need for manual intervention between runs’.

The automation options include a semi-automatic (manual load, automatic take-off) and a fully automatic load, take-off and stack configuration. The systems are designed to handle flexible and ‘difficult’ materials such as unconditioned corrugated board. There is also a 3/4 semi-automatic option which allows for single sheet, multiple sheet or double-sided print in registration; here, the operator loads onto a pre-load table from which the robots pick sheets and stack the printed output on a pallet.

A vacuum-based handling system for corrugated board is offered, as is a dual flex configuration that allows smooth switching between lay table loading and dual robot operation. There is also an optional High Five ‘flip to print’ mode for double-sided printing without manual intervention.

‘The new automation options available with the Onset X HS range are the result of close collaboration with our current Onset X customers,’ said Matt Brooks, head of products and solutions at Inca Digital. ‘Longer run full automation is becoming more and more common, and with the introduction of highly sophisticated robotic arms from ABB and Inca’s uniquely designed sheet pick-up technology, our Onset X customers can now produce extremely high volume, high quality print work in even less time. The ultra-high productivity and rapid job changeovers optimise production levels like never before.’

An Onset X3 HS Dual Flex making use of this automation was recently installed at ImageData in East Yorkshire.