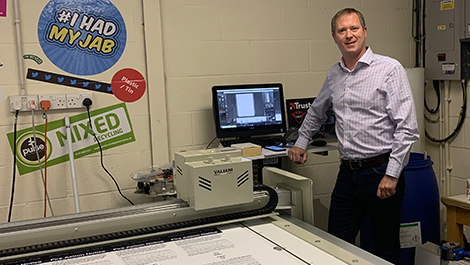

Wellington Press, a print company based ‘a stone’s throw’ from the Olympic Village in London’s East End, has replaced its Valiani Mat Pro Ultra V150 flatbed cutter with a Valiani Optima 160.

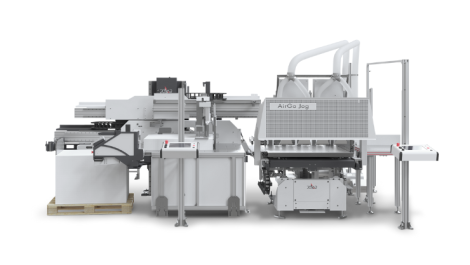

The Optima 160 machine is a vacuum flatbed die-cutting unit that is able to cut a wide range of materials and is described as ‘ideal’ for in-house prototyping, point-of-sale displays, or short to medium runs of packaging boxes. The new machine was installed by Morgana Systems, Valiani’s exclusive distributor in the UK.

‘We are now regularly handling thicker substrates,’ said Wellington’s managing director, Nick Murray. ‘The Optima 160 can cut up to 20mm, and we can now work on materials up to 1600 x 1230mm. It also allows us to produce work faster thanks largely to the twin head tool station. That means, for example, that we can cut and crease at the same time.

‘The V150 was a great product, and has served us well, but, as demand has grown, the time was right for us to move to a more capable and more productive machine.’

The 160 offers a vacuum table for holding the media in place, a twin headed tool station, and interchangeable accessories for cutting, half-cutting and creasing, drawing and oscillating, and perforating. A camera comes as standard for and, used in combination with the optional OptiCrop software, the unit can perform accurate contour cutting and creasing around pre-printed media, even with print-distorted materials.