Morgana has introduced the Docubind Pro VFX, a new option for twin-wire binding for lay-flat products such as education and training manuals, calendars and notebooks that it says offers higher productivity than manual alternatives but with greater flexibility than inline solutions.

The new machine combines Morgana’s high speed VFX vacuum feeder, which runs at up to 140 pages per minute, the StreamPunch VFX heavy duty punching and creasing module and the eWire VFX twin-wire binder, the latter engineered by GBC. The feeder was designed to increase ease of use and do away with the need for specialist operator training, while giving improved feed reliability. It can hold up to 5400 sheets at weights between 75 and 300gsm, including coated stocks.

The punch unit has a range of die sets for various hole types to support wire, coil and plastic comb binding, as well as basic creasing. Sheets up to 300gsm SRA3 can be punched and bound in the system or sent directly to the delivery tray for other applications. For binding within the unit, the eWire module draws from wire spools inside the cabinet, cuts to length and closes automatically, delivering bound books to a catch stacker. The wire is available in different sizes to suit documents up to 10mm in thickness, approximately 100 pages, depending on stock thickness, and in white, black or silver.

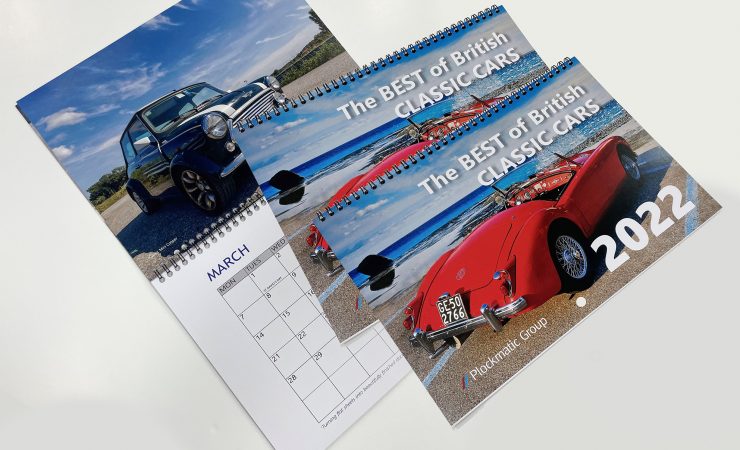

Ray Hillhouse, VP sales & marketing for the Plockmatic Group Offline Business Unit, commented, ‘This newly created, fully automated solution provides for significantly greater productivity versus manual production, and greater flexibility when compared to complex inline solutions. We see a sizeable gap in the market for such a compact, free-standing unit.’