Duplo has introduced two devices aimed at B2 digital printing, a B2+ version of the DuSense digital UV coater/foiler, and a cutting system that cuts down the larger sheets for further cutting, creasing and perforation in an existing multi-finisher.

The two machines were launched and demonstrated at an open house event held at the company’s Addlestone, Surrey showrooms, to an audience of dealers, distributors and customers, the first such event Duplo has been able to hold since before the Covid pandemic.

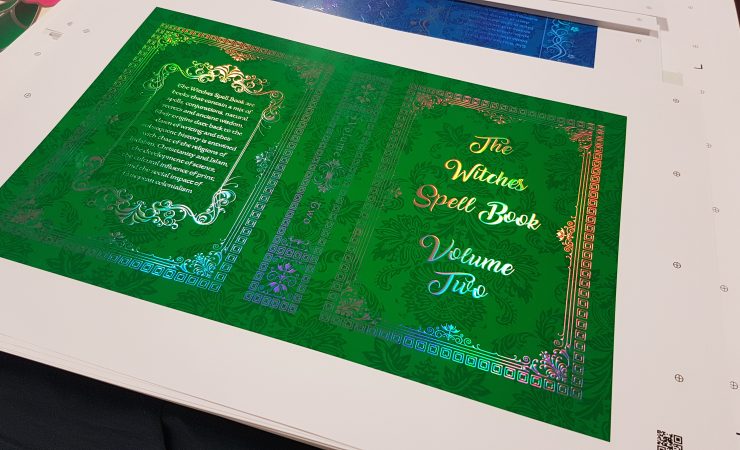

The DuSense DDC-8000 is a modular B2+ unit, able to handle sheets up to 585 x 1068mm, with a maximum ‘print’ area of 538 x 1048mm, a sheet size that prefigures forthcoming digital presses, according to Duplo. It is offered in four configurations, from Essential, which offers the digital spot UV coating at 600 x 600dpi, through a Foil variant which offers the digital foiling capability and a Pro version which adds media pretreatment to allow use with offset, dry toner and HP Indigo prints, to an Ultimate specification which includes everything. The length of the unit ranges from 5.2m in the Essential guise up to 6.6m in Ultimate form.

Substrates between 160 and 600gsm can be handled, allowing applications in folding cartons and related packaging. Auto Thickness Detection adjusts both printhead height and foiling roller pressure. The UV coating can be applied in thicknesses between 10 and 80 microns in a single pass, though product specialist Andy Cuff advised that most applications are in the 30 – 40 micron range and for thicker builds, a two-pass process would give better control for finely detailed work. Mercury lamp UV curing allows a maximum throughput of 1500sph.

Registration along the entire length of the sheet is achieved via a side-lay system and a camera is used to detect X-Y offset, stretch, skew or twist (shear) issues with the incoming printed sheet. The system also includes a barcode reader for variable data work, enabling different UV/foiling instructions to be called as each new job arrives. Up to five foil cores can be supported, allowing different colours or types of foil to be applied across the width of the sheet if desired; foil roll changes can be accomplished in around one minute, comparable to laminator systems.

The DC-20K cutting system cuts B2+ sheets into sizes that can be handled via the existing Duplo DC-746 slitter/cutter/creaser, to which it is linked inline via a feeder, which Duplo points out will maximise existing customers’ investment in the latter while enabling printers who are moving into B2 digital print in order to increase volumes or to replace more offset work to gain the benefits of the format without having to upgrade or replace all their SRA3 equipment.

Four applications were demonstrated, from standard business cards, where the B2 sheet size allows for 50% greater coverage at 64 per sheet versus 21 per sheet on SRA3, while 150mm square greetings cards also benefit from a better fit on the sheet and demonstrated the DC-20K’s ability to handle long or short edge feeding. An A4 landscape job with creasing and perforation along both axes was shown, and a nine-up A6 leaflet layout with off-centred cutting also demonstrated the productivity advantage of the B2 sheet size, though requiring the appropriate imposition for this type of finishing.

To this end, communication with EFI Fiery DFEs and Ultimate Technologies’ Impostrip are being developed. This is achieved via ‘lightweight’ XML code which is quick to process, and follows on from previous Duplo integrations with EFI front-ends, for its DC-648 and DC-616 units.

The DDC-8000 is available immediately and the DC-20K is expected to ship in summer 2022.