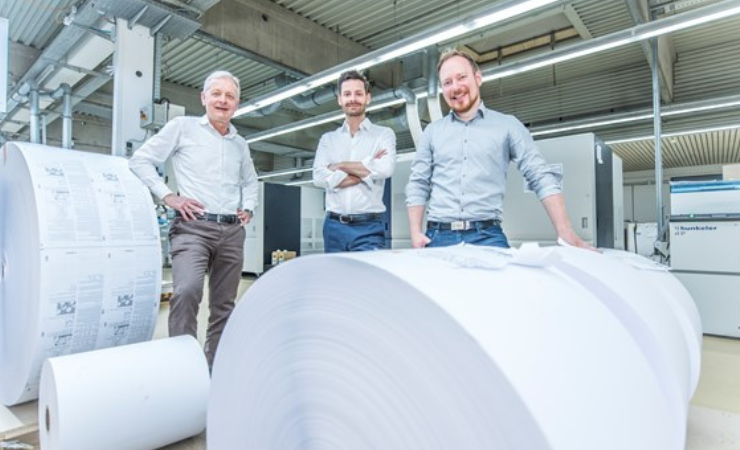

Pharmaceutical print specialist diePharmadrucker has extended its digital inkjet print capacity with the installation of a Screen Truepress Jet520HD mono web inkjet press.

The German-based company aims to become one of Europe’s first ‘fully digital’ print firms in the pharmaceutical print domain, offering the shortest delivery times.

The company, which also produces catalogues, labels and booklets, had already been using a (colour) Screen Truepress Jet520HD+ since June 2020. Since most pharmaceutical product inserts are monochrome, diePharmadrucker chose to expand its digital print capacity with the Truepress Jet520HD mono and aims to completely move away from offset printing by the end of 2022.

Strict requirements apply to printing pharmaceutical product inserts, packaging and leaflets. This means only certain types of papers can be used, information must be printed in specific fonts and sizes to ensure readability, and inks must meet international standards. Because of this, pharmaceuticals will continue to be required to add printed insertions to their products – making this market niche immune to the general shift to online marketing, according to the firm.

Managing director at diePharmadrucker, Conrad Fischer, said, ‘The genius of Screen’s inkjet technology is that it shortens time-to-market for our customers by eliminating several process steps.

‘We can also significantly reduce chemical usage, paper waste and storage capacity. So, the inkjet technology aligns with our zero waste approach by enabling us to take the next leap in reducing our own ecological footprint, and that of our customers.’

Patrick Jud, area director for Screen Europe, said, ‘Pharmaceutical package-insert production brings complex challenges in terms of a smooth and controlled production chain. It requires a great deal of expert knowledge. But diePharmadrucker printing pharmaceutical leaflets on inkjet machinery was game-changing for the pharmaceutical world.’