Leeds-based PDQ Printing Services has installed a Gibson GT-F3020 LED-UV flatbed printer, supplied by SOS (Service Offset Supplies) to meet a growing demand for the production of outdoor signs, especially for fairground clients.

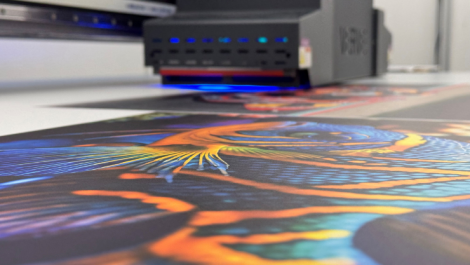

The Gibson machine, which can print directly to Correx board, has a maximum print area of 3.1m x 2m, Ricoh Gen6 print heads and uses LED-UV curing. The printhead assembly runs on a magnetic linear motor for reduced friction and maintenance.

Alison Blyth, who started the company 30 years ago, explained, ‘We were outsourcing this work, but the volumes became such that we saw the logic of bringing production in-house. We underwent a major reorganisation and some structural changes to the building to accommodate the machine, but it’s already proving worthwhile, not just in meeting existing demand but in attracting new orders.

‘We knew we wanted to produce 10 by 6ft sheets, whereas most flatbeds run 8 by 4ft. We approached some major suppliers for information, but were disappointed with the response. It was a huge contrast with SOS, who we have known for many years as our litho plate supplier. When we asked them if they sold flatbeds they immediately gave us a quote, some samples and all the information we needed. We now estimate we can produce as many as 200 boards every day.’

The company still runs a four-colour SRA2 and a two-colour B3 press, but also offers a full range of services including digital and wide-format.

The connection with the funfair industry is via family connections, said Ms Blyth. ‘My father was an engineer with a passion for restoring antique fairground rides, most famously the ‘Moon Rocket’ which was revolutionary when first built in the 1930s and is now working at The Dingles Fairground Museum in Devon.’