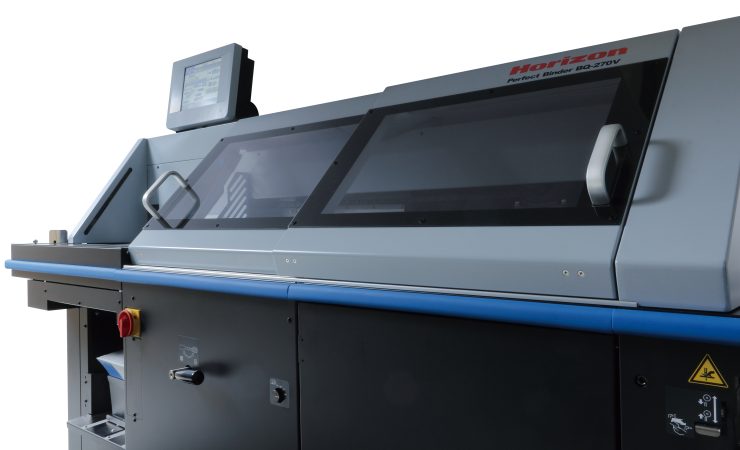

Greater Manchester-based Northern Collating has moved to future-proof its service offering with the addition of a Horizon BQ-270V single-clamp perfect binder from IFS.

The specialist finisher has 20 years’ experience, including Wire-o and coil binding, collating, shrink wrapping, guillotining and drilling. After moving into perfect binding with an entry-level system it decided the time was right to enhance its capabilities.

Managing director Neil Sanderson explained, ‘We dipped our toe into the perfect binding market a couple of years ago. Then we got to the stage where we wanted to have a faster, better quality system.

‘We liked the Horizon solution and we had heard a lot of good things about it. It is highly automated and easy to set up. Operators can jump quickly on and off it. Before we had to pre-score covers but now that is completed inline which saves time. It also seemed like parts were easy to get hold of if we ever needed to,’ he noted.

The 500cph BQ-270V supports on-demand production of variable thickness books, via an automated digital calliper system which measures book block thickness and automatically transfers this data to the binder for automated set-up for books of different thicknesses.

The unit has been running well, according to Mr Sanderson. ‘We are very pleased with it. It has helped us future-proof the business. Perfect binding was not something we have pushed before but now we can. It also allows us to manage a variety of run lengths. We got a job in today that was 10 books and the customer could easily come back with 500. We can be prepared for that. We can also now confidently promote the service to customers and present ourselves as more of a one-stop-shop,’ he confirmed.