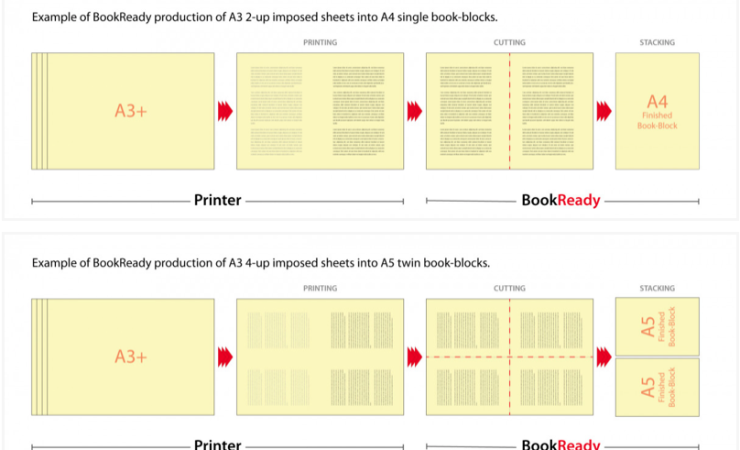

Tecnau has introduced BookReady, an inline cutting and stacking system that converts SRA3+ sheets printed 2- or 4-up into final size book blocks of up to A4 size ready for near-line perfect binding.

The system can change applications on-the-fly without manual intervention at full printing speed, according to Tecnau, enabling book printers to manage short runs and book on demand with exact page separation and no requirement for guillotine processing.

The new cut-sheet finishing solution may be equipped with an automatic 90-degree turning station to rotate 2-up imposed sheets from long-edge leading to short-edge leading, so that printer speed is maximised and ‘book of one’ production is possible. Book blocks are cut, stacked, offset separated and delivered to a belt conveyor ready for the next finishing process. BookReady is said also to feature a space efficient design ideal for book printers.

‘BookReady is designed to optimise production and facilitate finishing operations, building on the success of Tecnau’s Stack 1010 sheet-fed cutting/stacking system. The solution guarantees high efficiency while eliminating possible errors for customers who want to actively compete in the digital book sector for short runs and book-on-demand,’ commented Tecnau managing director Stefano De Marco.

Jason Seaber, technical sales director for Tecnau’s UK & Ireland distributor IFS, told Digital Printer, ‘The new Tecnau BookReady addresses a very important need that most book printers have by eliminating the need to take printed sheets, imposed 2-up or 4-up, from their printer to a traditional guillotine for cutting down, with the operator then having to manually separate these stacks into separated book blocks for near-line binding.

‘With fully automatic job size changeover, book blocks large and small can be produced on demand, at full printer speed, with 100% integrity and with no manual touch points. This can save book printers up to 33% in labour and reduce the unit cost per book.’