Konica Minolta Sensing and Screen Europe have developed a colour management workflow for the Truepress Jet 520HD web press which the companies say will make colour management faster, easier, more accurate and more reliable.

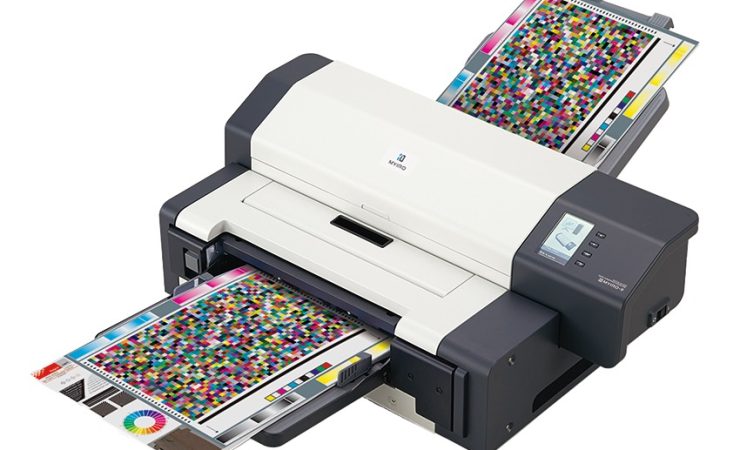

All Truepress Jet 520HD presses will now be equipped with the MyIro (‘iro’ is Japanese for colour) automatic colour calibration software and auto-scanning spectrophotometer from Konica Minolta, replacing manual colour calibration processes that required skilled staff and could take several hours. The new system integrates all steps in the calibration process software, guiding users through the density adjustment, linearisation and ICC profiling.

The new auto-scan spectrophotometer is said to speed the measuring processes by some four times compared to the previously-used measuring table, with the entire calibration process now taking 30 to 45 minutes, representing a time saving of between 90 minutes to two hours per machine setup.

‘Colour calibration is the essential, final step in the setup of a printing process,’ said Markus Hitzler, technical sales manager Graphic Arts at Konica Minolta Sensing Europe. ‘This step ultimately determines whether the qualities of the press, paper and ink can be fully utilised. It also has a significant influence on commercial aspects, such as ink consumption.’

‘The big difference with our previous system will be the standard built-in quality control, complying to common industry standards such as Fogra PSD, G7 Verify and ISO validation print, because this is what our customers will use every day,’ noted Taishi Motoshige, marketing director at Screen Europe. ‘Thanks to the spectrophotometer, our customers will detect colour differences before the human eye can see them, earlier than before, and in much more detail.’

There will also be options to adopt the new software and spectrophotometer for existing Truepress Jet 520HD customers.