Following the successful installation of its first InterioJet press in 2021, décor paper printing company Chiyoda has acquired a second InterioJet water-based inkjet printing press from Agfa to enhance its laminate décor paper print production capabilities.

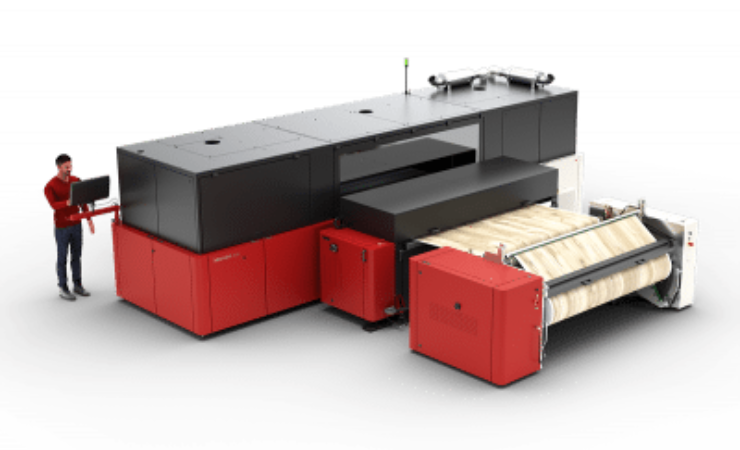

Chiyoda supplies printed décor paper with exclusive designs to flooring, furniture and car laminate panel makers, catering to their unique requirements. The new InterioJet 2250i will be installed at the company’s European headquarters in Belgium, joining the original InterioJet 3300i.

The InterioJet presses are driven by Agfa’s Asanti workflow software, which includes a plug-in for décor image optimisation. By working in conjunction with the industry-standard Ava CAD CAM software, Agfa claims to ensure a close match to gravure prints to guarantee consistent results.

‘The InterioJet has proven to be an invaluable addition to our operations, offering unparalleled print quality and great versatility,’ commented Peter Coenegrachts, COO of Chiyoda. ‘Our customers can use the prints in exactly the same way as gravure prints without any modification to their laminate production process. By investing in a second press, we are further expanding our capability to do shorter print runs, allowing us to meet the increasing demand for prints on demand and just-in-time deliveries.’

‘We are delighted to extend our partnership with Chiyoda to drive the digital printing revolution in the laminated surface market,’ said Mike Horsten, business manager InterioJet at Agfa. ‘Building on Agfa’s expertise in chemistry, inks and software, the InterioJet ensures the highest print quality and colour consistency. We are thrilled to witness how our presses cater perfectly to Chiyoda’s needs and enable them to deliver exceptional products to their customers.’