Durst Group has expanded its P5 wide-format portfolio with a raft of enhancements to automation, flexibility, speed, software, services and sustainability, announced at Fespa.

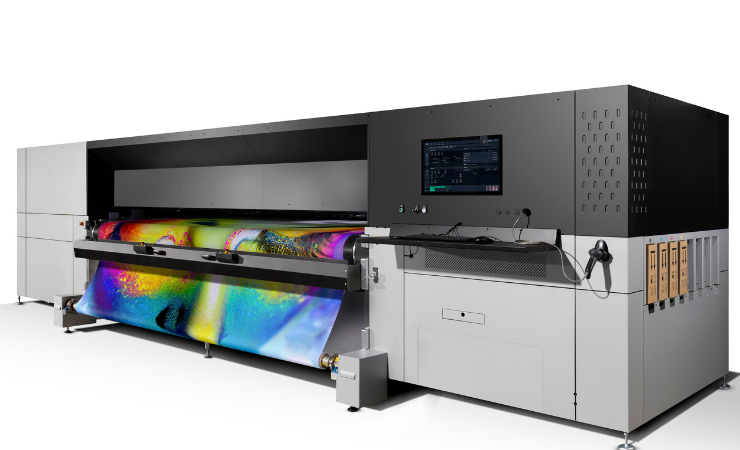

Durst’s P5 350 HS hybrid printer is joined by an ‘ultra-fast’ counterpart for roll-to-roll applications, the P5 350 HSR. The P5 HSR is a 3.5m LED roll-to-roll printer capable of speeds of up to 670sqm/hr and can be equipped with an optional master roll. This can feed rolls weighing up to 1000kg and 635mm in diameter, enabling long production cycles without interruption.

The printing system can be equipped as with double CMYK. For printing mesh and perforated material, the 350 HSR offers ink dust-free processing with the integrated mesh printing system. It also enables fast material changeover, which can be carried out by a single operator. Efficiency can be further increased via optional vertical and horizontal cutting units, which operate inline with the printing process.

Durst has also invested further in software development in recent years, and currently uses its Analytics software to monitor more than 900 printers in production at customers’ sites in order to ensure the continuous availability via preventive maintenance measures. Over 600 sites also use Durst Workflow for their prepress and print preparation steps, and 150 Smart Shops are in use at web-to-print providers to enable seamless connection from the web store to production. In Europe, 45 Lift ERP solutions have now also been installed, bringing together business processes such as warehouse management, logistics and accounting with print production.

Durst also used Fespa to demonstrate its P5 Robotics option for maximum speed unattended overnight printing, which complements the auto-stacking system that was previously available. A new addition to the Vanguard line, the 3.2 x 2m flatbed VK3220T-HS flatbed, was given its world premiere.