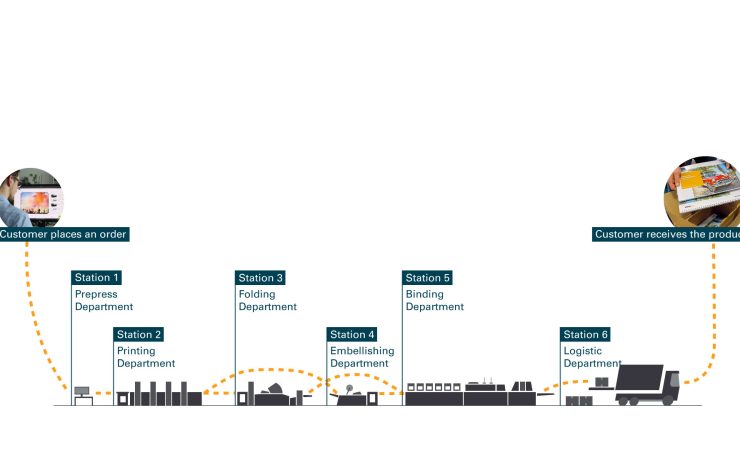

Wide-format workflow software developer OneVision has introduced v23.1 of its eponymous software, which introduces the concept of ‘production stations’ to support production control and monitoring across the whole process from order entry to shipping logistics.

The newly-developed model allows instructions and information on specific work steps to be automatically passed on to users at different production stations, such as prepress, printing, embellishment or binding. Users at the stations can record the implementation of process steps according to job specifications as live feedback to the workflow management system. This enables print service providers to digitally track the production status of their products in a transparent manner.

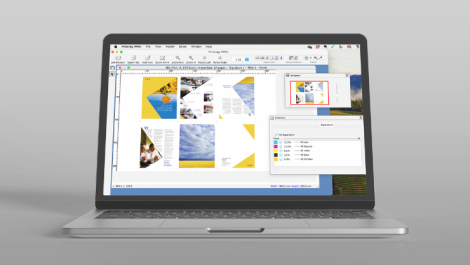

OneVision’s workflow management system has also been expanded in the new version in terms of customisation of dashboards, in order to reflect the requirements of different user roles.

To allow even more precise, and hence resource-saving, nesting in wide-format work, marks can now also be placed between objects automatically. As a further improvement, the length of the cutting line after nesting is provided as a job property for subsequent calculation of the time required and therefore the cutting costs.