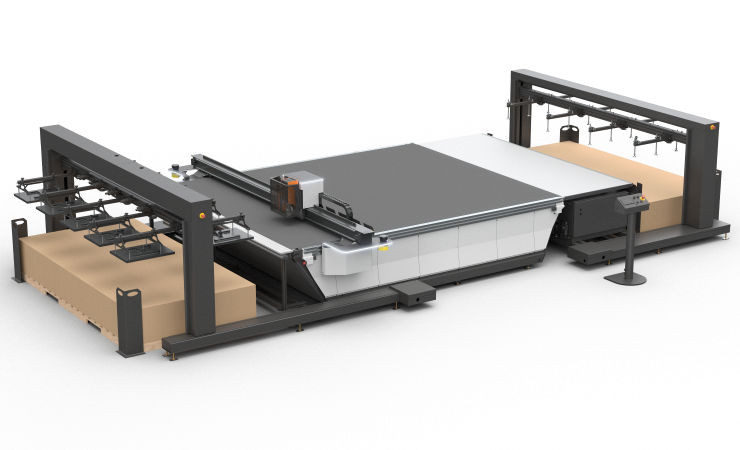

Kongsberg Precision Cutting Systems has introduced the Kongsberg Ultimate, a high productivity digital cutting table aimed at users of corrugated board in sign, display, PoS and packaging.

The new machine is said to offer ‘unprecedented’ levels of productivity, precision and safety. It features a new drive technology and carbon fibre beam design that enable acceleration of up to 2.74G and cutting speeds up to 168m/min in order to address the challenges of continuous high volume multi-batch production.

The carbon fibre beam also provided ‘unparalleled’ stiffness and consistency in applying 50kg downforce. Complemented by a toolhead camera, this is claimed to bring accuracy and repeatability to the highest industry standards.

Safety features include Kongsberg Smartzone, a proximity-driven dual-zone system designed to achieve safety and efficiency. This is supported by LED lighting to convey machine status in a highly visible manner. Uptime is helped via new self-diagnostics and remote operator alerts, while a productive operator experience is delivered via a touchscreen running the IPC 3.0 interface.

‘Engineered with our deep understanding of corrugated and display converters’ needs for precision, the Kongsberg Ultimate promises to redefine standards and usher in a new era of productivity and innovation, delivering a fast return on investment for convertors of corrugated board,’ said Kongsberg PCS president and CEO Stuart Fox. ‘Enhancing operations and providing a significant competitive advantage, the platform sets a new industry benchmark and is set to drive the future of corrugated production for years to come.

‘With corrugated converters around the world under increasing pressure to produce better, faster, safer and more efficiently to meet the demands of the global market, we have underlined our commitment to deliver a solution that has been engineered for precision and built for productivity,’ he added.