Duplo has introduced the iSaddle Senshi, a new saddle-stitching system that it says fits into a category between booklet-makers and conventional saddle-stitchers, where it offers ‘unmatched performance’. It is designed to provide increased overall productivity through flexibility in configuration and application, and is able to bind up to 5050 30-sheet A5 booklets an hour, offering heavy-duty stitching.

Named to reflect the company’s Japanese heritage (‘senshi’ means warrior), the new machine operates from the flat sheets typically produced by digital presses, rather than the folded signatures found in offset-based production. Duplo says that removing the requirement for this folding step reduces the requirement for skilled folder operators in favour of simpler guillotining processes, while still offering high quality flat bound products.

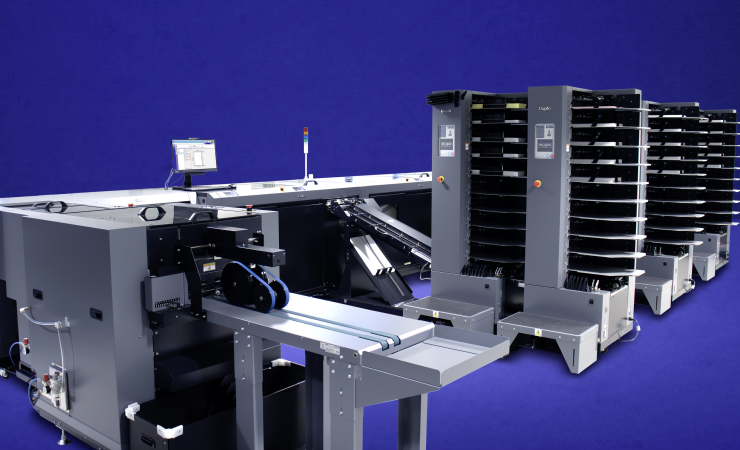

Quick make-ready is supported by multiple tower configurations that allow subsequent jobs to be loaded and prepped while the machine is running, plus quick switching to allow short run high priority work to be sandwiched in between longer-run or less urgent work. Automation-driven setup for new jobs is achieved in 45 seconds, with the calibration run completed in under two minutes.

Duplo’s Peter Dawson also told Digital Printer that, ‘An unexpected benefit we found from the pilot site was that unlike a regular C-shape where the loading and unloading compete for space, the different layout allows for much better access. Our pilot site will be running a job of 220,000 and when dealing with such large numbers, you need to be able to efficiently bring in and remove pallets of work and take away the finished books. All of these operator tasks add up to affect the true ‘books on the floor’ at the end of a shift’.

The Senshi’s automation is largely based on that of the existing iSaddle 5. Mr Dawson noted that maintaining the same easy job programming, automated set-up and fine adjustment were ‘crucial’, and confirmed that the new machine provide Industry 4.0 compliant reports in XML at the end of each run, suitable for ingestion to MIS or other production management systems.

He also explained, ‘Retaining the same level of features is not entirely necessary for the Senshi; for example options such as stacking flat sheets are unlikely to be a requirement for a conventional saddle stitcher. There are some features such as programming intelligent sheet feeding that are more relevant to lower volumes of digitally printed pre-collated work.’

Marine Kerivel-Brown, marketing manager at Duplo, added, ‘At Duplo, we understand that winning in any battle requires a combination of strength, intelligence and skill. With the iSaddle Senshi, we’ve created the perfect union between agility, accuracy and automation, encased in a robust frame engineered for heavy-duty production.’