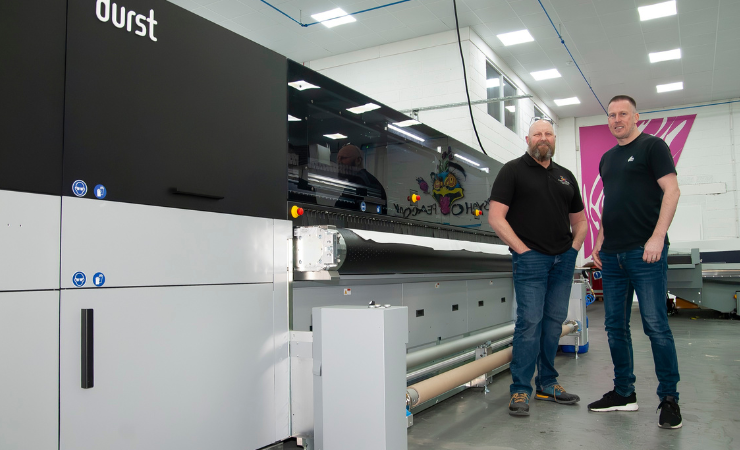

Psycho Peacock, a large-format specialist graphics supplier, has installed Durst’s P5 350 digital hybrid UV LED platform and P5 Tex iSub dye-sublimation direct-to-fabric printer to streamline logistics and provide faster installations for its customers.

A sister company to Full Circle Events & Exhibitions, Psycho Peacock is based in Salford, Greater Manchester and provides a service from design to installation for graphics in exhibitions, events, retail, museums, construction and visitor attractions. The investments are expected to provide up to six times the previous capacity, with the output from the previous four machines produced by the already installed and profiled P5 350.

Steve Comar, Psycho Peacock’s managing director, commented, ‘This investment gives us the scope and resources to fully deliver on our goals for both graphics and print, across our key sectors, live events, exhibitions and retail for the next three years. We can be assured due to the Durst technology, incredible quality and output metrics, that we can stand by our commitment to continually drive innovation which underpins our values and clients’ needs.’

The Tex iSub production printer is said to have opened up new business opportunities with dye sublimation for Psycho Peacock. The company said the investment in ‘cutting-edge machinery epitomising speed, quality and efficiency’ will ‘revolutionise output.’

Andrew McIntyre, general manager at Psycho Peacock, added, ‘The big thing with the Durst is that it provides the highest print quality, massive extra capacity and flexibility. Dye-sub also enables us to produce sustainable products, using fully recyclable materials, which means waste never goes to landfill. This opens up new business possibilities in a year when we are already beating our own ambitious sales targets.’

‘Delighted’ with Psycho Peacock’s investment into Durst’s technology, Peter Bray, UK and Ireland managing director of Durst Group, said, ‘Offering complete solutions from pixel to output, we continue to lead by innovation and look forward to continuing to help the team fully deliver on their goals. Our technology will help them further with their sustainability goals, commitment to excellence, streamlining logistics and moving towards greater automation.’