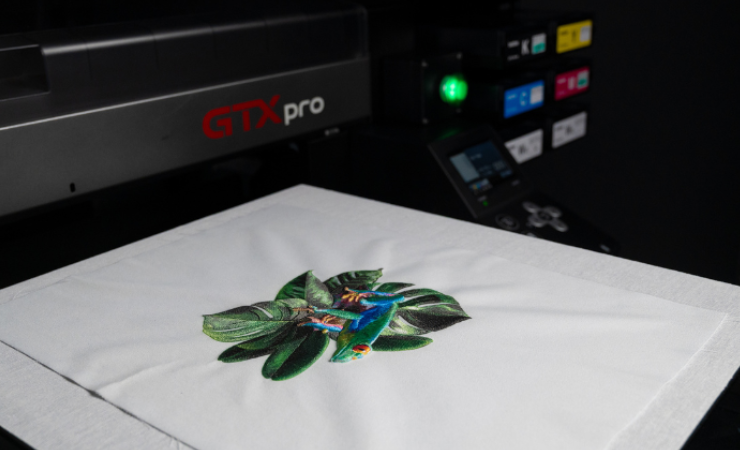

The printing industry is constantly changing. Innovative new ideas for even more optimised textile printing are regularly launched. Brother presented one such option at this year’s Fespa, the innovative direct to embroidery (DTE) printing solution. Put simply, DTE is the combination of embroidery and direct to garment printing – embroidered designs with a 1200Dpi print on top. Suited for large runs or personalised small runs – it makes no difference for this combination.

With this addition to their portfolio, Brother is expanding the possibilities for decoration with a GTX series printer. By using a high-resolution camera and specially developed software, the print design and the embroidery are combined in a unique and outstanding look. The connected camera system recognises the position of the embroidery on the printing plate and forwards the print image to the printer in the exact position of the embroidery.

The workflow is also very user-friendly, as the embroidery image does not have to be aligned in detail on the printing plate. The camera system scans the embroidery area, regardless of whether the embroidery is rotated or upside down on the plate. By scanning through the camera, the print is placed exactly on the stitch, almost eliminating misprints.

The GTXpro series printers do not need to be converted for this process. Only the camera and the associated software need to be connected to the printer. In addition, the process for this printing method on an embroidery is identical to the classic direct to garment printing.

The special aspect about DTE is that only a white thread is needed for the embroidery. The white embroidery image can be refined with the water-based and GOTS-certified Brother inks. This enables many unique possibilities in the embroidery sector: vibrant and bright colours, colour gradients, transparencies, and a fast workflow.