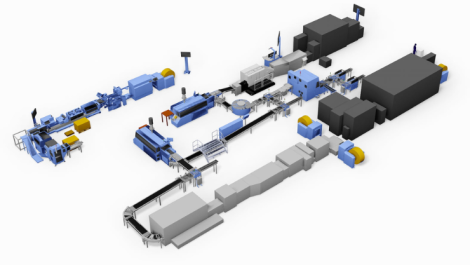

Moulton Printing has chosen to invest in the UK’s first Horizon iCE StitchLiner Mark IV next generation saddle-stitching system from IFS.

The Blackpool-based commercial printer was keen to expand its service offering and develop its online service delivery and the newest evolution of Horizon’s StitchLiner technology that incorporates Horizon’s cloud-based iCE LiNK workflow as standard has enabled the 97 year old company to do just that.

Cassie Moulton, third generation of Moulton Printing, explained, ‘We have been wanting to expand our online services but were concerned about managing any bottlenecks. We didn’t want to open the floodgates, in terms of orders, and potentially struggle capacity wise. The new StitchLiner has made this a real possibility.’

She continued, ‘It has made a significant difference to productivity already. The make ready is really quick and the interface is very user friendly. The whole process, from installation through to day-to-day operating has been much more straight forward than I was anticipating. It also gives us much more flexibility in terms of our product offering as it enables us to do sizes we have not been able to do before mechanically such as A4 landscape, A6 and DL. Taking all this into consideration, as well as the increase in speed, we are really flying through the production of our books.’

Moulton Printing’s Horizon iCE StitchLiner Mark IV achieves high quality booklet production at speeds of up to 6,000 booklets per hour. It’s cloud-based iCE LiNK uses cloud technology to automate workflow from upstream to post-press.It provides access to an intuitive easy to use dashboard that reports real-time production analysis for improved efficiency and profitability, remote update capabilities and scheduled maintenance resulting in less downtime. The information is accessible via smartphone, tablet or desktop PC and the software is designed for integration with MIS systems.